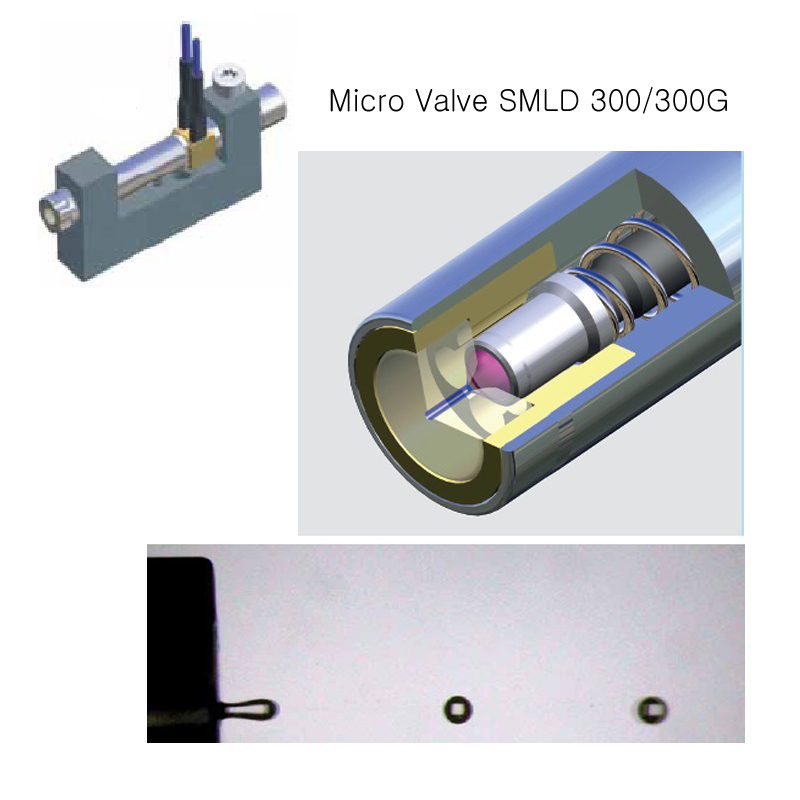

Micro Nozzle Valve

마이크로 노즐 밸브 Valve > Valve Module > Micro Nozzle Valve- 제품설명

-

- ml, nl Dispensing Micro Valve Nozzle

- 최고의 정확성, 정밀도, 재현성, 신뢰성을 갖는 밸브구조

- Maker : Fritz Gyger AG / Switzerland

- 연락처

-

경기본사 : 031-790-1907 (내선3)

대전지사 : 042-824-5167

-

Dispensing media : 물, 시약, 오일, UV-접착제, 페이스트 등

-

Dispensing Speed up : 4,000 Hz

- Dispensing volume : 10nl 이하 가능함

-

Hard Seling 구조 : 사파이어와 루비

-

높은 반복성

-

비접촉식 Dispensing에 최적화

-

패턴 최소 폭 4mm

Functional Priciple

1. Valve seat, valve nozzle

2. Closing spring

3. Valve coil

4. Stationary anchor

5. Medium

6. Valve ball

7. Mobile anchor

8. Switch

마이크로 밸브는 전자 기적으로 작동하고, 액체는 바로 그것을 통해 흐름.전류가없는 경우, 마이크로 밸브는 폐쇄. Closing spring은 Valve ball과 Mobile anchor에 작용함. 상기 valve coile에 전류가 공급되면, valve ball이 mobile anchor와 Stationary anchor의 자기장에 의해 당겨지고, 마이크로 밸브가 열리면서 액체가 디스펜싱 되는 구조.

Valve Struture

The hard-sealing valve structure makes precise opening strokes possible of a few hundredths of a millimeter and repeat accuracies in the range of thousandths of a millimeter.

The short opening travel and the correct actuation allow the micro valve to be switched 4000 times per second long-term. The finely ground and polished optimal inner forms of the valve nozzle and valve seat provide the best possible flow properties before emergence. This results in an exactly dispensing jet for contactless dispensing and optimal drop formation.

Additional guide elements in and around the hard material components and the already mentioned advantages, if properly applied, make for a long micro valve life-time. By using these high-quality materials, high chemical and mechanical resistance and compatibility values are also achieved.

1. Closing spring

2. Valve ball

3. Valve seat, valve nozzle

Thanks to the use of hard materials for the valve seat (sapphire) and the valve ball (ruby), unrivalled possibilities open up for micro valve applications.

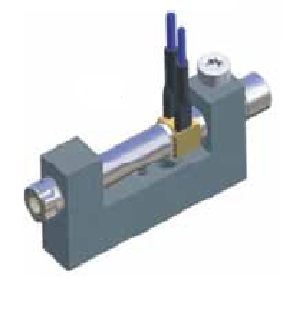

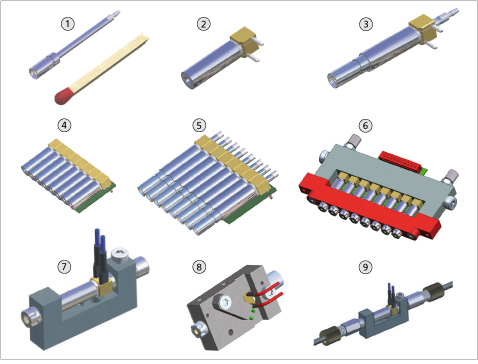

MODULAR STRUCTURE, MICRO VALVES SMLD

- 1. Micro valve with tube connector

- 2. Valve coil

- 3. Micro valve with valve coil

- 4. 8 valve coils on printed circuit board

- 5. Coil package with 8 micro valves

- 6. Dispensing module with 8 micro valves

- 7. Valve holder with micro valve

- 8. Heated valve holder with micro valve

- 9. Micro valve, inline variant

MICRO VALVE SELECTION

The right micro valve is selected primarily based on the following influential parameters and properties:

- Dispensing media, viscosity, temperature

- Dispensing time, dispensing volume

- Medium feeder, pressure

| Viscosities | Low Up to 110 mPa.s |

Medium 110 – 500 mPa.s |

High 500 – 15000 mPa.s |

|

Dispensing media |

Gases |

Mineral oils |

Greases |

|

Minimal dispensing |

under 10 nl |

more than 50 nl |

more than 200 nl |

|

volume |

|||

|

Medium pressure |

1 – 5 bar |

3 – 12 bar |

8 – 50 bar |

|

Temperature |

Room temperature |

30 -70° C |

50 -100° C |

|

Nozzle diameter |

Ø 0.10 and Ø 0.15 mm |

Ø 0.20 and Ø 0.30 mm |

Ø 0.45 and Ø 0.60 mm |

|

Travel |

0.03 and 0.06 mm |

0,10 mm |

0.10 and 0.15 mm |

Dispensing Volume

A minimal dispensing volume is achieved with the optimal nozzle diameter, a valve travel corresponding to the medium and a fast and precise actuation of the micro valves. Our modular valve controller MVC 1 is wellsuited for the best possible actuation. Up to 16 micro valves can be actuated independently of one another with the MVC 1.

Medium presure

If possible, the medium should be discharged from a pressure container. If the medium takes on air, this can lead to fluctuations in the dispensing volume as well as to satellite splatters. To prevent this, solutions are available where the medium and the air are separated by a piston. In order to not have to operate the dispensing system under an unnecessarily high pressure, we specially recommend that the cross section of the supply line up to the micro valve be selected as large as possible for highly viscous media.

Temperature

When using media with a higher viscosity which cannot be dispensed at room temperature, the medium can be heated. The viscosity is then changed, and optimal dispensability is achieved. Micro valve heating is limited to 100°C by the valve coil. The micro valves can withstand a much higher temperature, however. Our MVC 1 can also control up to 4 heating systems.

Relationship betwen nozzle diameter and valve Travel

Nozzle diameter and valve travel are important influential parameters for the drop formation. To achieve the best dispensing results, the nozzle diameter and the valve travel have to be matched and combined with each other. The table shows the recommended standard combinations. Larger nozzle diameters and valve travel are used for larger flow volumes and media with higher viscosity. Smaller diameters with small valve travel are suitable for small dispensing volumes for the longest life-time.

Determining the valve type

SMLD 300, the fast one

If a medium of low viscosity is used, and if the highest speeds of up to 4000 Hz and the highest dynamics are required, the micro valve SMLD 300 is used. This valve type offers a small inner volume of only 25 ul and a minimum pattern width of 4 mm for cramped spatial conditions.

SMLD 300G, the flexible one

If there is enough of space and if the inner volume of 65 ul is suitable for the application requirements, the micro valve SMLD 300G is used. The micro valve is available with all established nozzle diameters. It can be combined with a valve holder with an integrated heater. This allows dispensing in the entire possible viscosity range.

Valve Holder

The valve holder concept for the micro solenoid valves SMLD 300 und 300G of Gyger is adjusted on the needs of different applications and highlighted by the easy handling. It is possible to integrate the holders into an existing customised system or into a machine.

The assembling of the valve holder takes a few easy steps. The change of a micro solenoid valve can be done fast without disassembling the whole valve holder.

The assortment of the valve holders varies on the connectors and depends on the requirements of the customers.

The valve holder with the integrated heater is suited for special high viscose mediums.

THE VALVE HOLDER ASSORTMENT

The assortment of the valve holders varies on the connectors and depends on the requirements of the customers. Please give us your application; we are pleased to recommend you the compatible valve holder.

| Different Connector Versions | Including Integrated Heating for High Viscose Mediums |

Inline Version |

DESIGN VALVE HOLDER

The assembling of the valve holder takes a few easy steps.

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/halterzerlegen_1.gif)

CHANGE MICRO SOLENOID VALVE

The change of a micro solenoid valve can be done fast without disassembling the whole valve holder.

MOUNTING OF THE VALVE HOLDER

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/montageprinzip1.gif)

Back Mounting Concept

The mounting of the valve holder in an existing system or machine can be done in 2 different ways. It doas no matter, if the choice was for a SMLD 300 or SMLD 300G. Both holders are mounted at the same height and the dosing goes off the same position.

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/montageprinzip2.gif)

Front Mounting Concept

The mounting of the valve holder in an existing system or machine can be done in 2 different ways. It doas no matter, if the choice was for a SMLD 300 or SMLD 300G. Both holders are mounted at the same height and the dosing goes off the same position.

MVC Valve Controller

MVC 1 – COMPLETE INTEGRATED SOLUTION

The modular valve controller MVC-1 of Gyger provides a complete solution for dispensing applications depending on customer’s needs. The valves and heaters will be configured by a serial interface (RS232 or USB) via Java-Software or direct with commands. This allows the customers, focussed on the requirements of their applications, to integrate the MVC-1 as an intelligent driver module in existing systems or to use it as a capable stand alone solution.

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/mvc_overview_de_1.jpg)

MVC-SOFTWARE

The MVC-Software (Java based) allows a comfortable handling via graphic interface. In the software all driver modules and there functions are visualized. The corresponding parameters (e.g. valve opening-time, heater temperature) can be easily set and tuned on the dispensing application.

The functions can be controlled direct from the Software (e.g. triggering dispensings), in addition different modes can be set, which allows the operation only over external Hardwar-I/O-signals. Complete configuration can be saved on the hard disk and reloaded on demand.

MVC 1-Software main screen |

Edit valve-properties |

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/mvc_hauptmenu_de.jpg) |

![[Keine Beschreibung eingegeben]](http://www.fluidics.ch/files/mvc_ventiledit_de.jpg) |

SYSTEM OVERVIEW

![[Keine Beschreibung eingegeben]](http://fgyger.ch/files/mvc_masse.jpg)

![[Keine Beschreibung eingegeben]](http://fgyger.ch/files/system_e.jpg)

Depending on customers application the MVC 1 is available in the following configuration levels: |

||

| 2 micro valves and 1 heater4 micro valves4 micro valves and 2 heaters6 micro valves and 1 heater

6 micro valves and 3 heaters |

8 micro valves8 micro valves and 2 heaters8 micro valves and 4 heaters10 micro valves and 1 heater

10 micro valves and 3 heaters |

12 micro valves12 micro valves and 2 heaters14 micro valves and 1 heater16 micro valves |